Engineering Capabilities leading to innovative, custom and complete fastener and

component solutions.

Pro/ENGINEER CAD Systems

Advanced CAD systems help ITW engineers shorten the product development cycle of

fastenings systems from several months to days. Pro/ENGINEER is the industry's de

facto standard 3D mechanical design suite. Much of its success can be attributed

to its patent-pending, award-winning technology which spurs engineers to more quickly

and consistently innovate new products. ITW also has full translation capabilities

(CATIA, IDEAS, Unigraphics, etc.) for customer math data exchange.

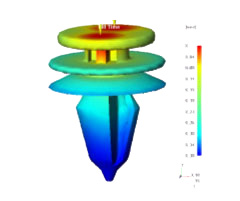

Finite Element Analysis

The Mechanical Event Simulation package that we use combines the capabilities of

kinematics and FEA to simultaneously replicate motion, flexing, and stresses of

a fastening system during a hypothetical “event.” Engineers at ITW can perform nonlinear

static stress analysis using powerful nonlinear material models to predict deflection,

deformation, and insertion-extraction force data. This allows ITW to optimize the

part design and product performance, and shorten the product development cycle.

Moldflow Analysis

Seamless integration with CAD solid models means engineers run simulations and view

results directly on the solid model. The software identifies critical manufacturability

and quality issues and recommends appropriate actions to address those issues. This

ensures ITW will get the design into production as quickly as possible.

With theses tools, ITW engineers are able to take control of their designs early

on, enabling every part and mold concept to be tested for manufacturing feasibility

before the tool is cut.

Moldflow Analysis allows ITW Engineers to determine the best possible manufacturing

scenarios for each design.

Design is optimized for injection molding process to achieve highest CONFIDENCE

OF FILL before tool steel is cut.

Our Engineers are experienced professionals ready to get involved from the initial

concept stages through the final assembly process to develop a product that lives

up to our customer’s expectations. They also understand that design is really “art

and practicality” rolled into one. At ITW Deltar Fasteners, raw creativity,

fashioned by advanced CAD/CAE engineering, tooling, the latest thermoplastic resins,

robotic systems, computers, and high quality through statistical process control,

all contribute to the final product. ITW is organized into more than 400 operating

units, aligned by core businesses. This global organization affords ITW Engineered

Fasteners access to innovative ideas and processes from its affiliated divisions

around the world.